An abrasive is a tool, or substance, which, because of its structure and high hardness, is used to polish, abrade, roughen, roughen, finish, sharpen, grind, lapping, scrape, scrape, hone, refine or burnish another material by mechanical action.

These materials must have a hardness greater than 7 on the scale of hardness. scale of hardness to be able to perform their functions.

This tool is commonly used in industries such as carpentry, construction, metallurgy, automotive mechanics and even in craft industries.

In their use, machines such as polishers, belt sanders, grinders, grinders, grinders, miter saws, saws or cutting or grinding discs are used.

Content

What are the types of abrasives that exist?

There are several types of abrasives, which are first classified as natural and synthetic.

A natural abrasive, as its name indicates, is one that has its origin in nature, some examples are: diamonds, pumice, quartz, garnet and emery.

Despite the fact that since ancient times humans have resorted to the use of natural abrasives, their use is currently not recommended, especially if you want to obtain a professional result, since they contain a high degree of impurities in their structure, therefore, the final product may not meet quality standards.

On the other hand, if a combination of different raw materials and chemical reagents is used to obtain an abrasive product, it will be classified as synthetic or artificial.

These include: vegetable abrasives, aluminum oxide, silicon carbide, cubic boron nitride, synthetic diamonds, steel and stainless steel shot and discs.

There is a great variety of synthetic abrasives, so, depending on their components and structure, they are used for different purposes. For example, the vegetable abrasive, manufactured from walnut and/or almond shells, is perfect for delicate jobs such as removing paint without affecting the base material, as well as treating and cleaning delicate surfaces such as sculptures.

Grain

The abrasive grain is the mineral particle, previously treated, which comes into direct contact with the surface to be treated and therefore performs the function of cutting, removing or wearing of the desired material, so that, depending on the level of grain with which it is treated, it can be determined whether it is ideal or not for the task to be performed.

To choose the ideal grain, it is necessary to know its size, for example, coarse grain is commonly used for soft materials, whose finish should not be perfect and a large area needs to be covered. On the other hand, the fine grain is used for harder and more fragile materials, whose result must be more graceful, such as glass.

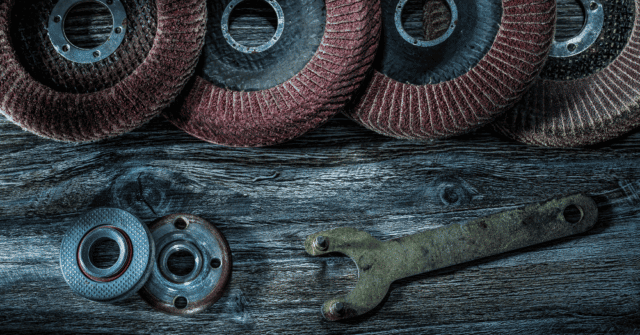

Discs

As their name indicates, they are discs that can be used in fixed or portable machinery to fulfill their abrasive function.

They are composed of a series of abrasive grains, and depending on the composition of their grains, they are classified as: cutting disc, grinding disc and sanding disc.